What’s for dinner tomorrow? Food for thought

Lab-grown meat, bug chocolate and synthetic whisky may be acquired tastes, but they might be better for the environment – so entrepreneurs are getting busy

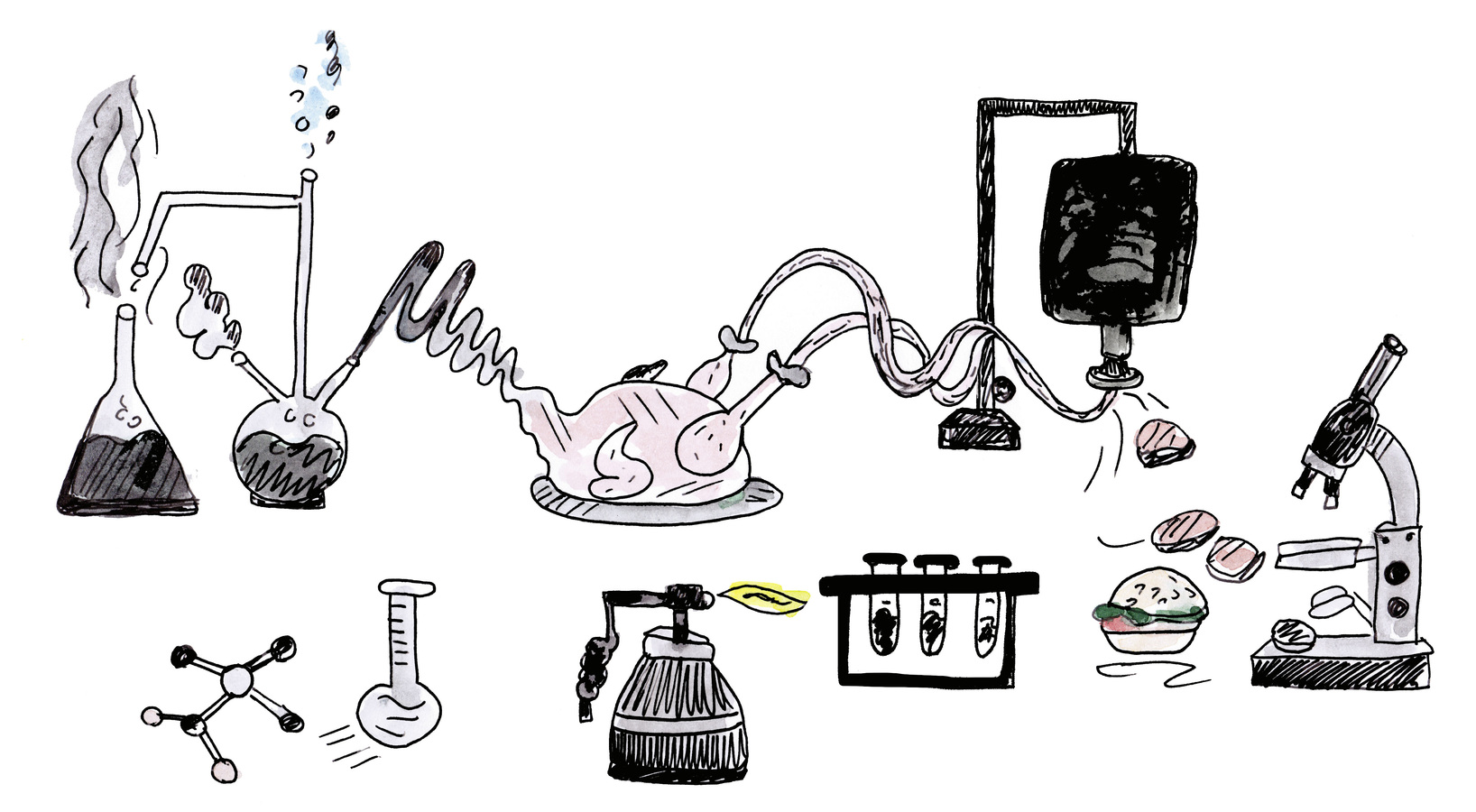

Lab-grown meat

How do you fancy meatballs and pâté de foie gras grown in a laboratory? Many entrepreneurs think in-vitro meat is the future. This year, the German food group PHW, which includes the poultry brand Wiesenhof, invested in the Israeli startup SuperMeat. A surprising choice, as success for Super Meat could make Wiesenhof’s chickens redundant.

The basic idea is simple: cell cultures from cows, pigs, chickens or geese can be multiplied in a nutrient solution to produce genuine beef, pork, chicken or goose meat for hamburgers, chicken nuggets or sausages. Several startups are vying to come up with the first product. Mosa Meat from the Netherlands started the race. In 2013, Mark Post, a physiologist from Maastricht University and later founder of Mosa Meat, presented the first hamburger made of beef stem cells – live to camera. Since then the pioneers have simplified and speeded up meat-cultivation techniques. Back then the burger cost €250,000. Post estimates today’s production costs at about €5,000 (£4,400). The aim is to produce the lab-grown burgers on an industrial scale and for the same price as the ones made of traditional meat. In July, the pharmaceuticals firm Merck, experienced in cell cultures, bought a stake in his company.

For the burgers grown in petri dishes to taste like ones made from animals raised in fields, the producers are now not only breeding lean muscle but also fatty tissue from cows, pigs or chickens. However, this requires antibiotics to avoid contamination. Another problem is that to make the cells divide rapidly, the companies currently need foetal bovine serum, which is produced from the blood of living but as yet unborn calves. “Which is not compatible with animal welfare,” the inventors at Maastricht University freely admit. That is why researchers are feverishly searching for alternative nutrient mediums, preferably plant-based.

Many industry experts are convinced that burgers and other meat products will soon be emerging from the lab. A survey carried out by the Karlsruhe Institute for Technology Assessment and Systems Analysis revealed that most customers would accept lab-grown meat. Shortages might indeed create a market for it. World demand for meat is predicted to rise by 70% by the year 2050. To meet this demand through traditional livestock farming, more space would be needed to produce cattle feed and emissions of greenhouse gases would rise still further. “One single solution won’t be enough. So we will be seeing lab-grown meat, and food made of insects, especially in Asia, and more and more plant-based imitation meat in Europe,” predicts Martin Schüring, the director of innovation at the Technology Transfer Centre in Bremerhaven, northern Germany.

Hamburgers, meatballs and chicken nuggets will be the first products to emerge from the lab. The animal cells can be pressed together using a binding agent such as egg white. Three-dimensional cuts such as steaks or ham hocks are harder to make, because the cells only grow to half a millimetre in the nutrient medium. To make something bigger, they need an edible framework to grow on – made of algae or polysaccharides. So meat from the lab will never be as convincing to the discriminating palate as old-fashioned sirloin from the butcher.

Bug chocolate

You won’t find any beetles’ legs in this very special bar of chocolate, however hard you look: it is white and smooth and melts on the tongue. “It tastes like white chocolate,” says Volker Heinz, director of the Institute for Food Technologies in Quakenbrück, north-west Germany. A team there created the chocolate, but it is not in shops yet. Only the fat content is from insects. Usually white cocoa butter is used. But in the bug chocolate the melting texture comes from white fat from mealworms or black soldier flies. Researchers extract it from the dead creatures by gently heating them.

The process may appear exotic, but it has a serious background – and a future, according to the independent food expert Christian Zacherl of the Fraunhofer Institute for Process Engineering and Packaging in Freising in Bavaria. Demand for cocoa is rising; about 4.5m tonnes is required every year. But supply fluctuates widely from year to year because the plantations are small and some of the trees are quite old. The industry has been seeking a substitute for a long time. The expensive cocoa butter can now be replaced by insect fat; the cocoa powder needed to make dark chocolate is comparatively cheap.

Insects are on the march – two billion people are already eating them. In Asia grilled locusts and beetles are a popular street food. Insects have plenty of advantages: they are rich in protein and fat. Mealworms and black soldier fly larvae can be rapidly and easily bred. They don’t need water or antibiotics. Their fat tastes something between nutty and neutral, and behaves like solid cocoa butter. That is why Zacherl reckons food containing insect fat has a future in Europe. “European consumers have been accepting pure ingredients from insects for more than 30 years in hundreds of products, such as the red colouring agent cochineal. It is in sausages, desserts and confectionery,” he says. Insects were approved for consumption in the EU this year.

In Europe that will mainly mean food containing pure fat or protein from insects, such desserts and cheese. Whole insects don’t seem easily accepted here, according to early tests with insect burgers. “There is a certain disgust factor.”

Algae instead of palm oil

In the USA yellow algae oil has recently arrived in many shops. It has a neutral taste like sunflower oil, not fishy. Algae are widespread on land as well as sea, and it was in the sap of a German chestnut tree that the Dutch food and biochemicals company Corbion came across the microscopically small algae that are now creating the yellow oil for the supermarkets in metal vats. The oil is suitable for salads and for frying, says Corbion. And its unsaturated fatty acids mean it is also good for the heart. On the other hand, at about €30 a litre it is not cheap.

The firm sees a great future in algae oil and has invested several million euros. The German chemical company BASF and Mara Renewables of Canada are also marketing algae oils. The Canadian product is used instead of palm oil in baby food. And that is exactly where its potential lies, at least if the price comes down, because it could replace controversial palm oil.

Palm oil is the main fat used in foods. In 2015 the food industry used 60m tonnes of it. As demand grows, great natural forests in Malaysia and Indonesia are being logged to make way for yet more palm oil plantations. Palm oil is used in frozen pizzas, ready meals and cakes, spreads and biscuits. It is easier to be vegan than to avoid this fat. “It’s biotechnologically easier to improve algae than a 30-metre-tall palm tree,” says Volker Heinz from the German Institute of Food Technologies. “Algae can be designed to create a particular fat from carbon dioxide and sunlight.” His institute is experimenting with algae oils for sandwich spreads.

Sunflower ice cream

Creamy, dairy-free strawberry ice cream? Vegans and people with a lactose intolerance have been waiting for such a thing for a long time. Zacherl aims to produce such an ice cream from sunflowers. Blending the seed protein with water produces a curd-like mixture. Many firms are now waiting for a breakthrough from Zacherl’s team. “In less than two years we will have done it,” he says.

Every year sunflower oil mills produce thousands of tonnes of waste sunflower paste, which is usually compressed into animal feed cake. But Zacherl thinks it is far too good to end up in a feeding trough. Filtering out husks and fibre leaves white-beige curds with a neutral and slightly nutty taste. This can be made into ice cream or plant-based cheese or yoghurt without any ingredients of animal origin.

So far, vegan meat imitations nearly always contain soya, which is a problem because soya has to be transported from a long way away. In South America virgin forests are cleared for it. Zacherl’s vision means there could now be a local alternative. “Very many newcomers from the vegan sector and traditional food firms want our sunflower protein,” he says.

What firms would actually prefer is not a curd-like mixture but a powder that could be transported unrefrigerated by lorry or ship and easily stored. That is what Zacherl is now working on. He wants to separate out the skins and fibres from the compressed cake in a kind of wind tunnel then dry the mixture, leaving a white flour. “White is very much in demand, so strawberry and pistachio ice cream keep their nice colour.”

Artificial whiskey

The American firm Endless West has announced plans to launch a synthetic whiskey within months. This spirit will have no connection at all with barley. A real single-malt whisky requires at least 10 years’ storage in an oak barrel before it can be bottled. That is too long, too complicated and too far behind the times for the founders of Endless West. Chemists have long since identified many hundreds of whiskey ingredients, and high-quality whiskey aromas have been available for a long time.

Why wait 10 years if you can carefully blend the individual components, asks Alec Lee, co-founder and chief executive of Endless West. He also sees other advantages in synthetic whiskey; having never been in contact with grain, it contains no pesticides. “And naturally it is a lot more convenient than growing barley, malting it, fermenting it, distilling it and storing it for 10 years,” says Mark Strobl of the beverage research department at Geisenheim University, in western Germany. The only thing is that it will never be allowed to call itself “whiskey” in the EU. “So you will have to be prepared to stump up the cash to build the brand.”

In the past, the company founders tried their hand at synthetic wine with their startup Ava Winery. Back then Strobl warned: “As long as you can buy wine in the shops for a few cents per litre, this artificial wine will never be able to undercut that price.” Ava sent out sample cases for $50 (£38), then quietly disappeared. Nonetheless, Strobl sees the idea of synthetic whisky as a real economic proposition. What remains to be seen is whether consumers will take to a dram of “synthie malt”.